An IQF freezer is built for one key promise: individual pieces frozen separately, not stuck together. That matters because consumers want free-flowing frozen fruit, evenly portioned vegetables, and shrimp that can be poured straight from a bag into a pan. In industrial terms, IQF freezing is a quality differentiator. It supports better portion control, better appearance, and more consistent cooking outcomes. For producers, it can open doors to higher-value retail and foodservice contracts.

IQF stands for Individually Quick Frozen, and “quick” is not a marketing word here. It is the physics of freezing speed. Faster freezing reduces crystal size and helps preserve texture. At the same time, the freezer must manage product movement and spacing so items don’t touch and fuse together.

Which products benefit most from IQF

IQF freezer systems are commonly used for berries, peas, corn, diced vegetables, shrimp, small meat pieces, and many prepared ingredients. But the biggest gains happen when the product is sensitive to texture or when presentation matters. A berry that keeps its shape and releases minimal juice after thawing is worth more. A shrimp that stays firm rather than watery builds trust with chefs.

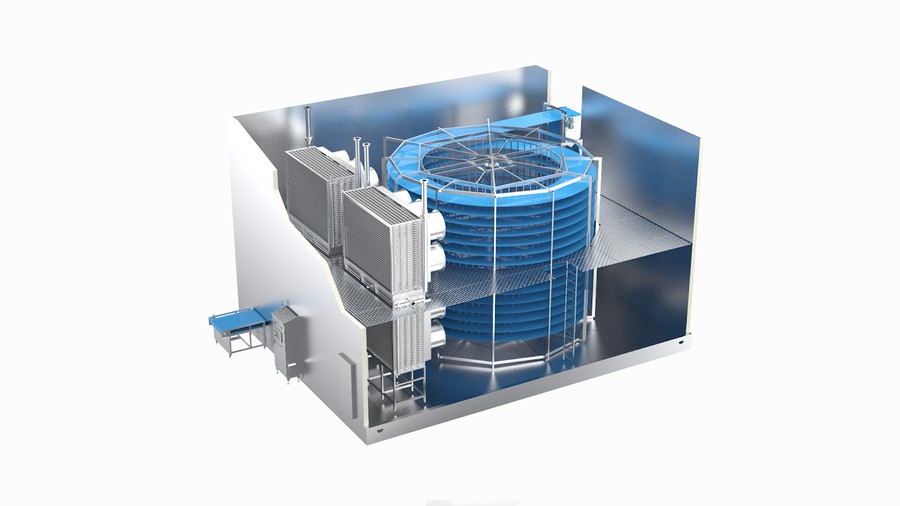

The role of airflow and agitation

An IQF freezer relies on carefully engineered airflow. Cold air has to reach all surfaces quickly and evenly. Many designs also use movement or vibration to keep items separated during the critical early phase of freezing. If separation fails early, you can end up with clusters and clumps that require mechanical breaking or product downgrading.

This is why industrial freezers designed for IQF are not interchangeable with generic blast freezing. They are tuned for product separation, gentle handling, and consistent freezing curves.

How to evaluate an IQF freezer for your operation

Start with your product size range and moisture level. Wet products can stick. Sticky marinades can create buildup. Very small pieces can get carried by airflow if the system isn’t designed correctly. Then look at throughput needs and how much variability you expect during production. If you run multiple products, the IQF freezer should support flexible settings and fast changeovers.

Energy use is another key factor. IQF systems can be efficient when designed well, but they still represent major operating costs. Insulation, fan design, and defrost strategies all influence power consumption and uptime.

IQF freezer integration with upstream and downstream steps

An IQF freezer doesn’t stand alone. A good line often includes dewatering, portioning, and a consistent feed system to deliver a stable bed of product into the freezer. Downstream, packaging must match the free-flowing output. When integration is done well, the system feels stable. When it is not, operators end up constantly adjusting feed rates or fighting clumps.

Why industrial buyers compare different industrial freezers for IQF

For many factories, IQF is a big investment and a big opportunity. That’s why buyers compare multiple industrial freezers and often shortlist well-known manufacturers. The goal is not only freezing speed but also free-flow performance, sanitation practicality, and service support.

Where Industrialfreezing.com fits

Industrialfreezing.com helps companies make sense of IQF freezer choices by focusing on real production needs. If you want premium frozen quality, IQF is a powerful tool, but only when the system matches your product behavior and daily operating reality.